Ode to Appalachia

Ode to Appalachia is an honors class run by Lisa Stinson partnered with The Beacon Butcher Bar Restaurant (in Boone, NC) centered around having two community-based dinners at the end of the semester, where students were in charge of creating the; theme, branding, marketing, making dishware, water cups, and selling items we made. Each student in the class was tasked with making at least six water cups and taking up at least one other making project. I ended up being a part, of the “Course One” group with Lela Arruza and Julia Boyce, where we made around Seventy- four aluminum bowls.

The dinner consisted of a five-course meal, and each night could sit sixty guests.

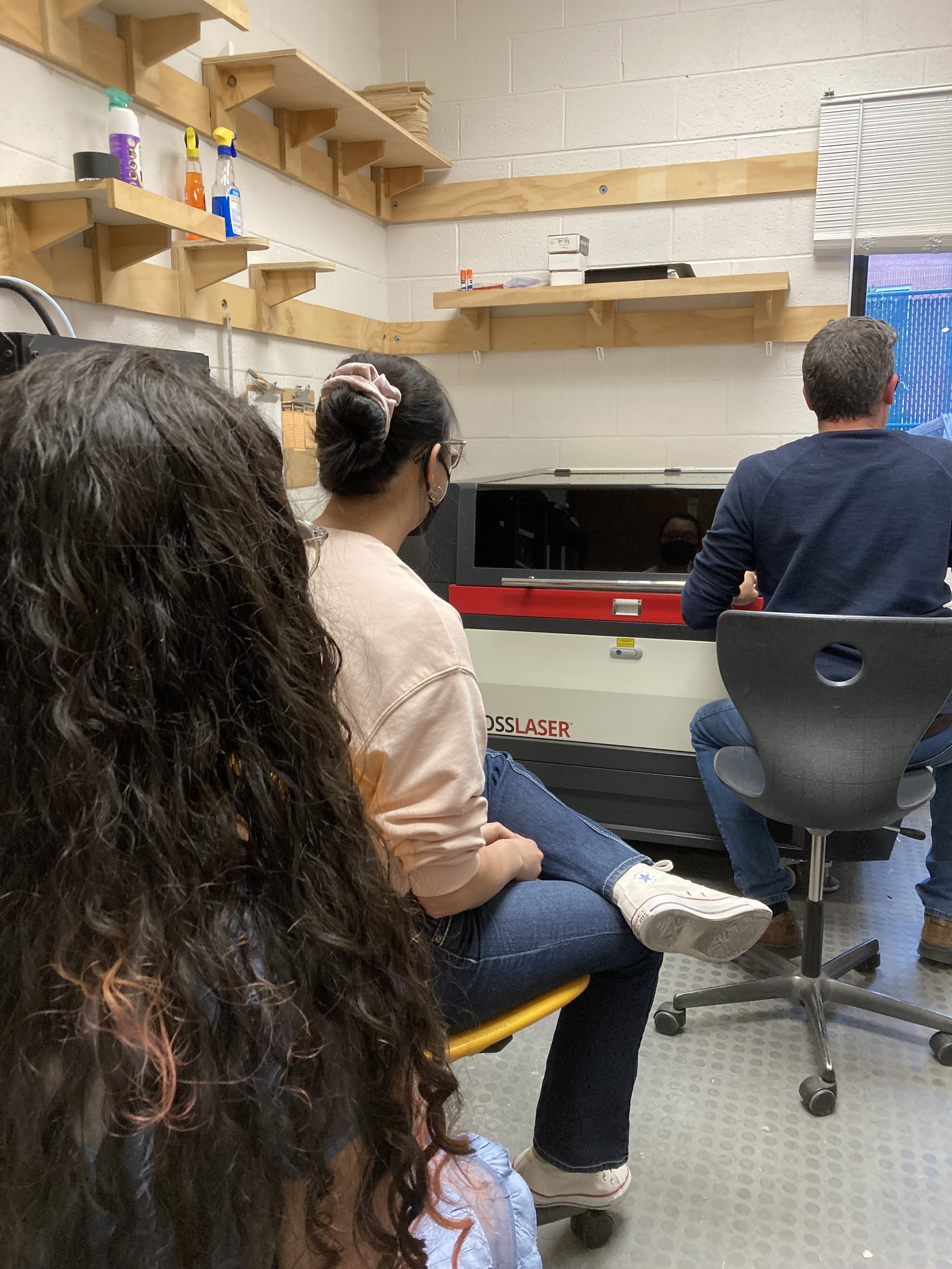

A huge thanks go to Frankie Flood, who was there to help out every step of the way, and Keela Dee, who helped with laser etching.

Making water Cups

-

Plaster Molds - Slip Cast

Each student was given a plastic water cup to cast in plaster. The process starts with getting an aluminum sheet and taping it up so the diameter is about 1” bigger than the cup diameter. Taking clay coils we attach the cup (upside down) to the table as well as the aluminum tube that we had taped up, ensuring no plaster will seep out. Next, we mixed up the plaster with a ratio of about 3:4 by weight and poured it into the empty mold. After about 10 minutes we were able to get our plaster mold.

-

Cleaning up Cast Cups

Once our plaster molds were made (waited a few days to dry) we were able to pour slip into the molds for about 28 minutes and then dump out the extra slip. Once the cups were leather hard we could carve them into the cups. After the cups were bisque fired, I applied different surfacing finishes to the cups. A combination of adding white and black slip.

-

Finished Cast Cups

After two rounds of adding glaze and sanding edges, I ended up with seven cups.

Course One - Making Aluminum Bowls

Photo taken by Lela A.

Lela showing Julia how to refine the form

Hydraulic Pressing the forms

Annealing the aluminum

Talking to Lisa about our process of forming the bowls

Frankie teaching Lela how to spin

Trimming the extra material off the spun forms

Frankie showing us how to anodize

Anodizing and dyeing set up

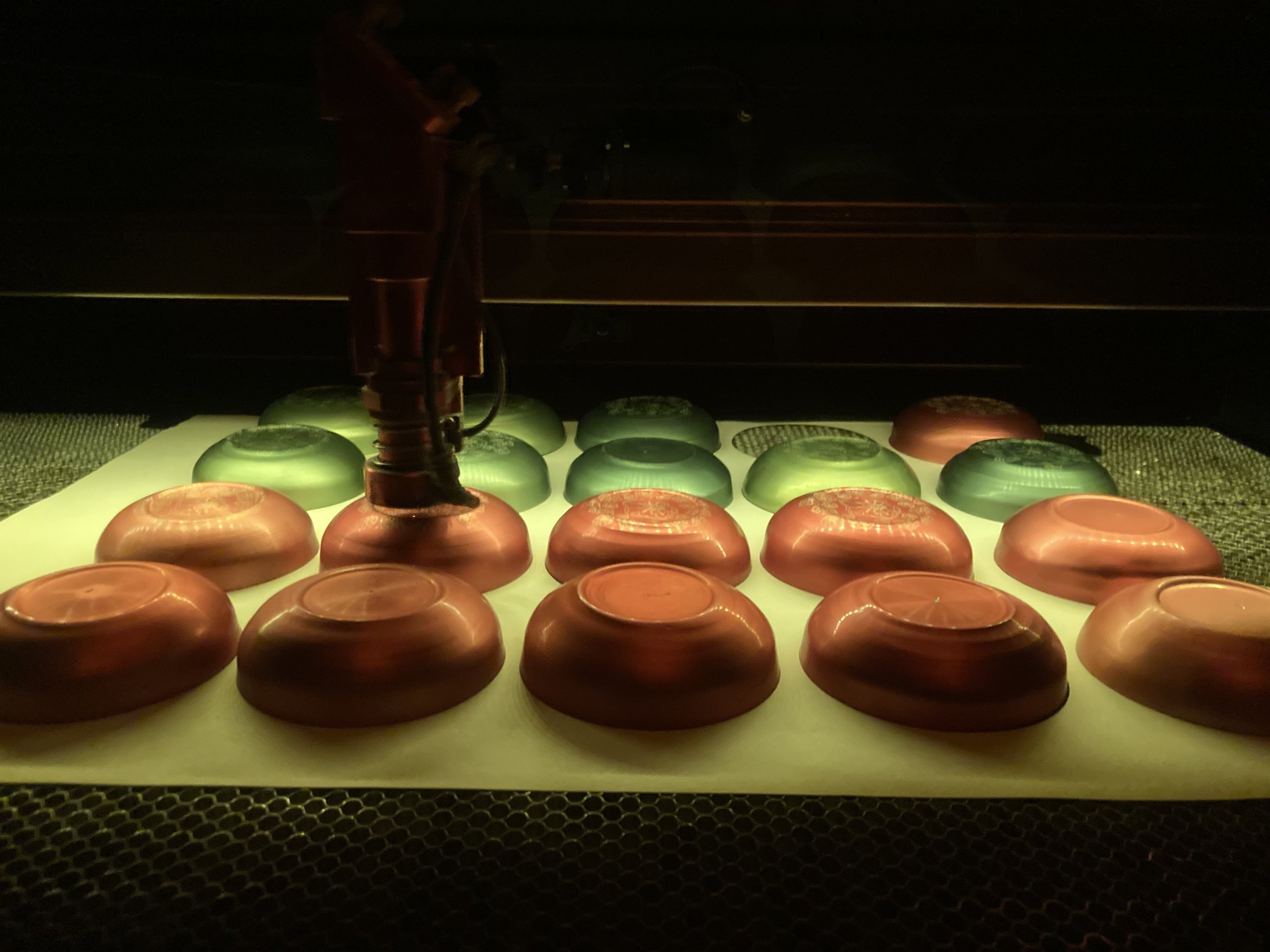

First laser etch attempt

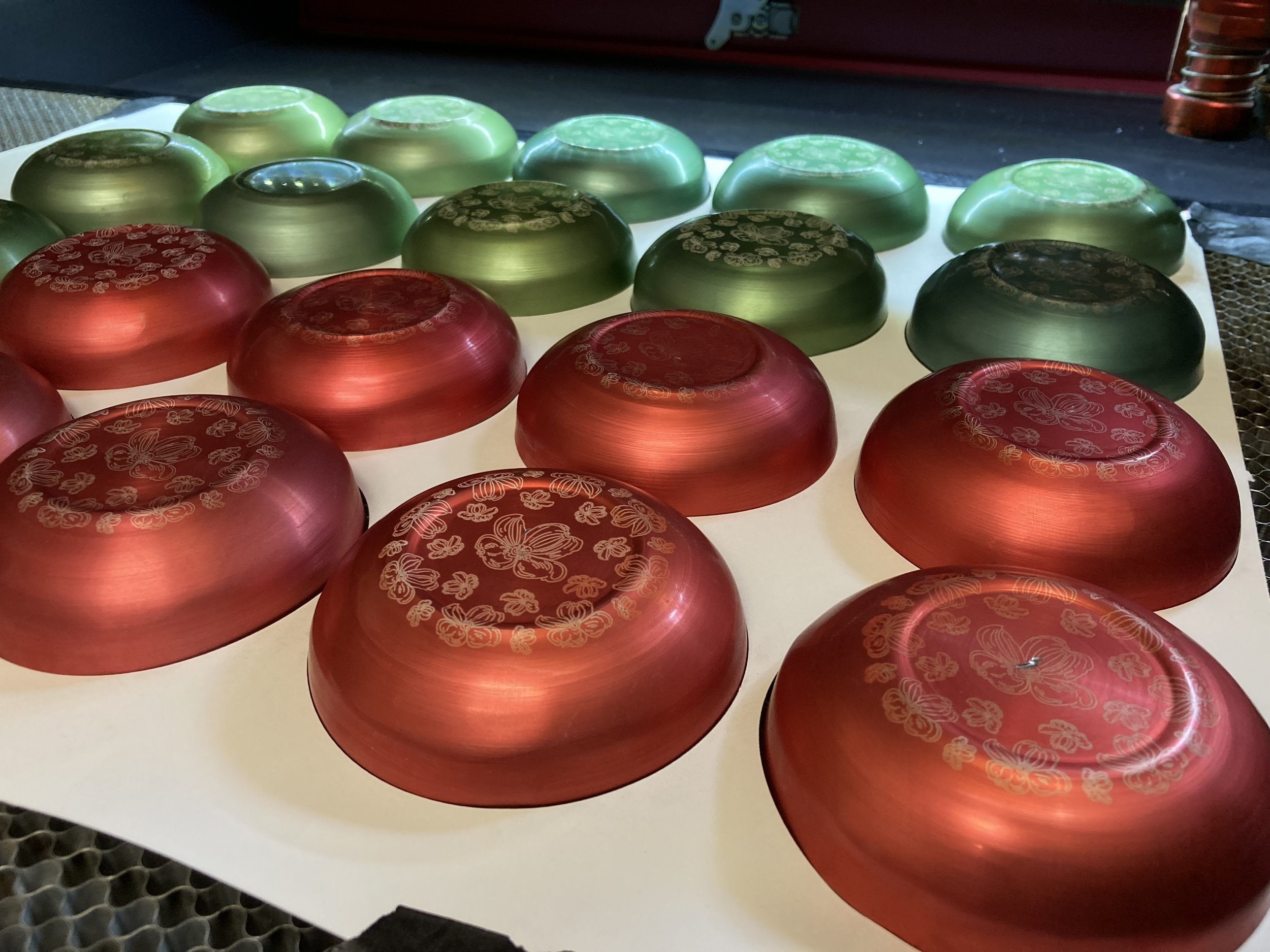

Laser etching Julia's designs

All the bowls waxed